Mixers & Agitators For Tanks

Engineered Magnetic Drive Mixing Solutions for Demanding Applications

Decades of Proven Performance in Engineered

Mixing Solutions

For over 30 years, MagnaSafe has been a trusted provider of high-performance tank agitators and mixing systems for critical industries including chemical processing, pharmaceuticals, food and beverage, and oil and gas. Our industrial tank mixers are engineered to meet extreme pressure, temperature, sanitary, and corrosion-resistance requirements, delivering safe, efficient, and contamination-free mixing.

From lab-scale setups to full-scale production systems, we design, and manufacture sealless top-entry, side-entry, and bottom-entry agitators for tanks tailored to your specific application and performance needs.

Engineered Liquid Mixing Technologies

MagnaSafe tank agitators and mixers are built for precision, reliability, and long-term durability in the most challenging environments. Whether you’re blending ingredients, suspending solids, dissolving powders, or managing heat and mass transfer, our mixers provide consistent, validated performance at every scale.

Key Features:

- Built for high-pressure and high-temperature applications

- Constructed from corrosion-resistant alloys specific to your process chemistry

- Designed to meet sanitary requirements for food, beverage, and biotech

- Available in explosion-proof (ATEX, UL, CSA) configurations

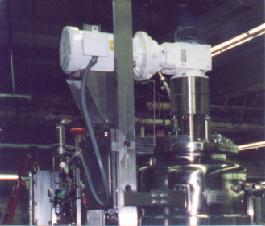

Industrial Tank Mixers for Every Configuration

MagnaSafe offers agitators for tanks that mount permanently to the top, bottom, or side of a vessel.Common mounting options include:

- Flange mount

- Plate mount

- Tri-clamp sanitary mount

- Threaded Mount

Whether you need a compact mixer for a research application or a powerful industrial tank agitator for large-scale storage and processing, MagnaSafe provides custom-engineered solutions that ensure product quality, safety, and compliance.

What Impellers Are Used in Tank Agitators & Mixers?

Hydrofoil impellers

For energy-efficient flow and blending

Radial flow impellers

For gas-liquid dispersion

Axial turbines

To prevent settling and maintain uniformity

Custom impeller combinations

For complex or multi-stage processes

Why Choose MagnaSafe Mixers And Agitators For Tanks?

Key Advantages:

- Horsepower range from fractional to over 50 HP

- Torque capabilities up to 50,000 in-lbs

- Fully certified: ISO, PED, ASME U, CE, CSA, CRN, UL, and ATEX

- Built for years of continuous service with minimal maintenance

- Easy to install, operate, and service

- In-house testing and CFD modeling to verify performance

- Personalized support throughout the product lifecycle

The Fusion of Process Mixing and Product Safety Through Mag-Drive Technology

Versatile, Contamination-Free Mixing for Critical Applications

MagnaSafe’s sealless mag-drive mixers and reactors are engineered for safe, sterile, and high-performance mixing across a wide range of industries and applications. Our technology is trusted in environments where leakage, contamination, or downtime cannot be tolerated—from pharmaceutical cleanrooms to oil field tanks.

Tank Agitators Engineered for a Wide Range of Applications

The MagnaSafe MST Top Entering Mixer is designed for industries that demand high-purity, precision-controlled mixing solutions in sanitary and chemical environments.

Pharmaceutical & Biotech

- Ideal for injectables, vaccines, cell cultures, and plasma/protein fractionation.

- Suitable for kilo labs and glass reactors requiring low-temperature processing.

Food & Beverage

- Designed for sterile mixing of citrus juices, food oils, soups, and beverages.

- Meets the highest standards for sanitary design and cleanability.

Chemical Reactions

Optimized for complex processes including:

- Alkylation, Amination, Bromination, Carboxylation

- Catalytic Reduction, Chlorination, Dehydrogenation, Esterification

- Ethoxylation, Halogenation, Hydrogenation, Methylation

- Nitration, Oxidation, Ozonization, Polymerization, SulphonationPerformed under high-pressure, vacuum, and temperature extremes.

Industrial & Research Use

Used in R&D centers, pilot plants, and full-scale manufacturing for:

- Fine & specialty chemicals

- APIs and bulk pharmaceuticals

- Dyes, intermediates, paints, agrochemicals, oils, and petrochemicals

Also trusted by defense agencies, universities, and research institutes for high-pressure experimental applications.

Extreme or Hazardous Conditions:

Proven effective with toxic and lethal chemicals, cryogenic reactions, and fermenters.

Zero-Leakage Performance—Where It Matters Most

Oil leakage in the field is unacceptable. Traditional mixers with mechanical seals are prone to wear and eventual failure, often requiring complicated replacement procedures—especially in full tanks.

MagnaSafe’s sealless magnetic drive mixers are the only solution offering true zero-leakage performance, with no seals to maintain or replace. This makes them the ideal choice for side-entry mixing in large oil storage and processing tanks where process integrity and operator safety are critical.

Sanitary Design Validated by Cleanability Testing

A rigorous cleanability study was conducted to validate the performance of a MagnaSafe bottom-entry mixer installed in a sanitary vessel.

Test Setup:

- Mixer surface was soiled with 1% BSA, 50% honey, and 100% corn oil—all inoculated with Escherichia coli and Staphylococcus epidermidis.

- The contaminants were mixed for 10 minutes, drained, and the impeller was tested for

residual bacteria, TOC, protein, and fat.

Drainage Results:

- Removed >99.89% of bacteria and >99.57% of TOC across all soils.

- Protein and fat were similarly removed during drainage—demonstrating minimal product loss due to impeller hang-up.

CIP (Clean-in-Place) Results:

- Post-CIP, >99.99% of residual bacteria were eliminated.

- All remaining TOC, protein, and fat were fully removed during the cleaning cycle.

MagnaSafe mixers not only maintain sterile processing environments but also demonstrate exceptional cleanability, supporting validation requirements in pharmaceutical and food-grade applications.

MST Top-Entry Tank Mixers

Ideal for large-scale ingredient blending and industrial food production.

MSB Bottom-Entry Tank Mixers

Designed for sterile, high-purity applications in dairy and pharmaceutical-grade food processing.

MSS Side-Entering Tank Mixers

The preferred solution for large-scale juice production, storage, and continuous blending.

Amar Mixers & Reactors

Perfect for small-scale research, formulation, and pilot testing before full-scale production.