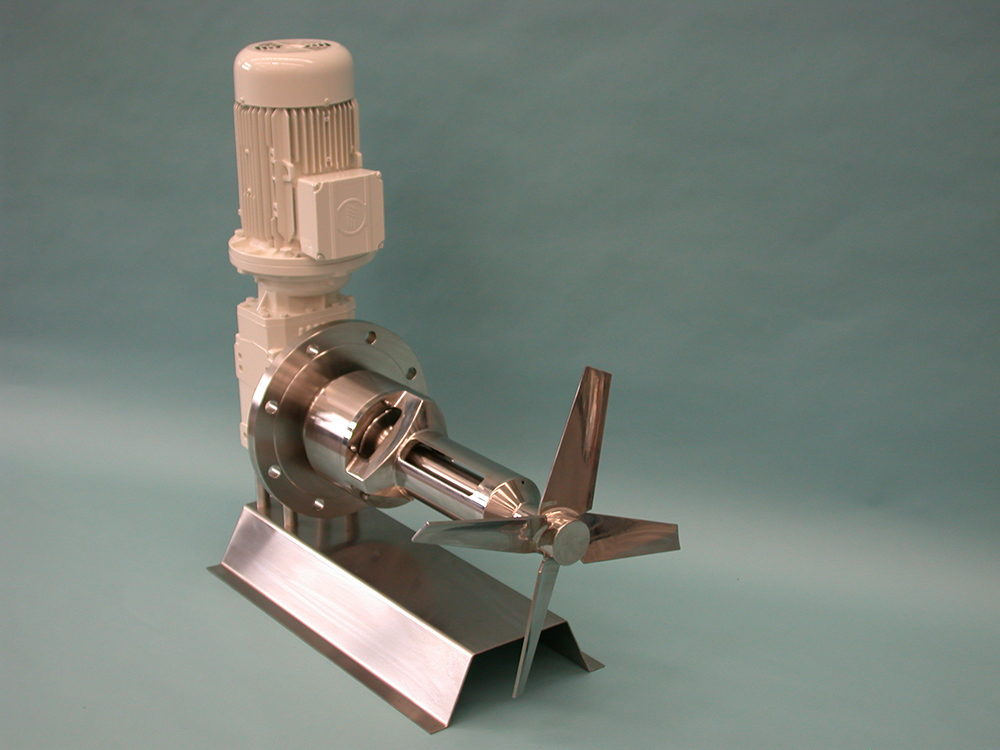

MagnaSafe Mag-Drive Side Entry Agitators & Mixers

Safe, Sealless, 100% Leakproof Mixing for Food, Chemical & Oil Applications

The MagnaSafe MSS Side Entry Tank Mixer is a high-performance, contamination-free mixing solution designed for oil, food, and chemical processing industries. Engineered with magnetic drive technology, this mixer eliminates mechanical seals, preventing liquid and vapor leakage, product contamination, and costly maintenance issues.

Built for durability and precision, the MSS Side Entry Tank Mixer is ideal for large storage tanks, blending applications, and high-pressure reactors, offering high-efficiency mixing with maximum reliability and safety.

Why Choose the MSS Side Entry Tank Mixer?

- 100% Leakproof Sealless Design – Eliminates leakage risks and ensures total containment of hazardous or sensitive products.

- Optimized Performance with CFD Technology – Uses Computational Fluid Dynamics (CFD) to fine-tune mixing efficiency before manufacturing, ensuring the ideal impeller selection and horsepower for each application.

- Minimal Maintenance, Maximum Efficiency – No mechanical seals = lower maintenance costs, fewer spare parts, less downtime, and less liability.

- Durable & Corrosion-Resistant Construction – Built to withstand high temperatures (up to 350°C) and aggressive chemicals.

- Customizable Configurations – Available in various materials, motor types, and installation options to meet unique process requirements.

- Each mixer is engineered using sophisticated computer software to ensure optimal mixing conditions for blending, emulsifying, and storage applications across industries.

Side Entry Agitator – Technical Highlights

Power Range: Up to 50 HP

Temperature Tolerance: 100°C to 350°C

Pressure Rating: Up to 3000 PSI, including double-wall containment shells

Flange Connection: Industry-standard for seamless installation

Motor Options: Electric, variable speed, air, or hydraulic

Material Options: Available in most alloys, glass lining, and specialized coatings

Bearing Options:

- Stainless steel lubricated and shielded

- Hybrid ceramic/stainless dry running

- All-ceramic dry running

Sanitary Features for Food & Beverage Applications:

- 15 Ra Polish for contamination-free surfaces

- All stainless steel drive

- Tri-clamp ferrule for secure connections

Additional Features:

- Zero-leakage magnetic coupling – no seal maintenance required

- Certified for ATEX Zone 0 applications

- Gear or belt drive options for plant preference

- Hydrofoil impeller for high efficiency with minimal power consumption

- Industry-standard installation with no swivel required

- Designed for 3 years of operation without maintenance

Industries & Applications

The MagnaSafe MSS Side Entering Tank Agitator is designed for industries requiring high-efficiency mixing, durability, and contamination-free operation:

Oil & Gas

Ideal for oil storage tanks, crude oil blending, and petroleum processing.

Chemical Processing

Designed for chemical reactors, hazardous material containment, and high-pressure environments.

Food & Beverage

Optimized for juice mixing, ingredient blending, and large-scale food production.

Download the Case Study: Blending & Suspension in Oil & Gas Storage Tanks

Oil storage and blending present unique challenges, especially when dealing with crude oil sedimentation. Proper mixing is essential to keep solids suspended and ensure consistent processing. This case study explores how MagnaSafe’s sealless side entry tank mixers provide an effective, leakproof solution that eliminates maintenance concerns and enhances efficiency. Learn how Computational Fluid Dynamics (CFD) plays a crucial role in optimizing mixer performance and why MagnaSafe technology is the preferred choice for zero-leakage, high-efficiency mixing in the oil and gas industry.

Frequently Asked Questions (FAQ)

How does magnetic drive technology work?

The MagnaSafe MSS Side Entry Tank Agitator features a robust magnetic coupling that transmits torque from the motor to the impeller without the need for a mechanical seal. This design eliminates leakage, minimizes contamination risks, and lowers maintenance expenses when compared to conventional sealed mixers.

What industries use side entry mixers?

How does CFD technology improve mixing efficiency?

before manufacturing. This allows our engineers to optimize impeller selection, motor horsepower, and flow dynamics, ensuring maximum efficiency and product consistency while reducing energy consumption.

Can this mixer handle aggressive chemicals?

What are the maintenance requirements?

Unlike traditional mixers with mechanical seals that wear out and require frequent replacement, the MSS Side-Entering Mixer is sealless and virtually maintenance-free. Designed for three years of operation without servicing, it eliminates costly downtime and reduces overall operating costs.

Is the mixer compatible with explosion-proof environments?

Upgrade to a No Maintenance, Leakproof Mixing Solution

With minimal maintenance, no leakage, and the highest quality mixing performance, the MagnaSafe MSS Side Entering Mixer is the ideal solution for large-scale storage and blending applications.