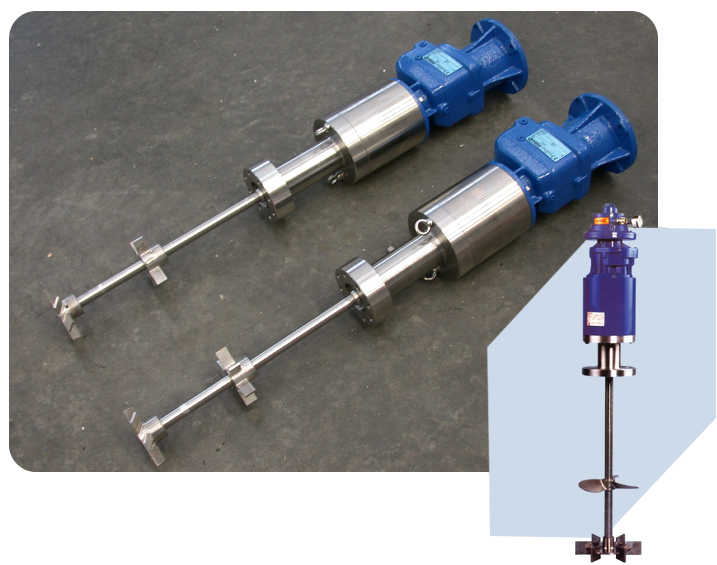

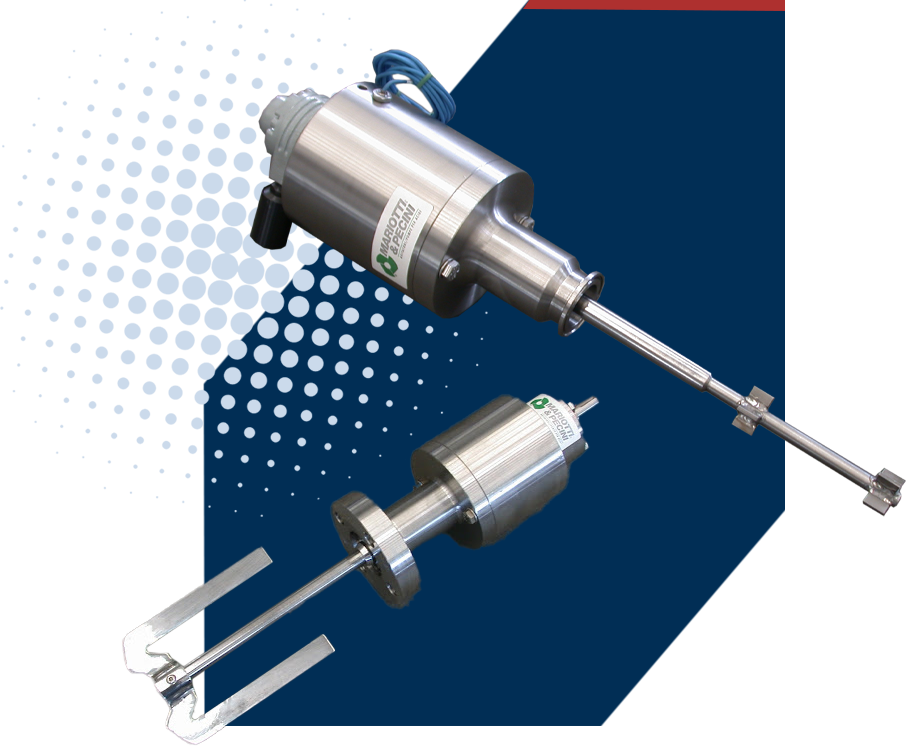

MagnaSafe Mag-Drive Top Entry Agitators & Mixers

Leakproof, Sealless Mixing for Chemical, Oil, Pharmaceutical, Biotech & Food Applications

The MagnaSafe MST Top Entering Mixer is a high-performance, contamination-free mixing solution designed for pharmaceutical, biotech, food, and chemical processing industries. Engineered with magnetic drive technology, this mixer ensures leakproof operation, eliminates vapor leakage, and prevents product contamination while reducing maintenance costs and downtime.

Built for precision mixing, high-pressure applications, and demanding sanitary standards, the MST Top-Entering Mixer is durable, highly efficient, and adaptable to a wide range of process requirements.

Top Entry Mixers Designed for Performance & Reliability

The MST Top Entering Mixer incorporates advanced engineering and fluid dynamics to maximize efficiency and ensure seamless integration into your process. Computational Fluid Dynamics (CFD) modeling is used to evaluate each application, optimizing impeller selection, torque requirements, and mixing performance before manufacturing.

With a rugged, corrosion-resistant design, the MST mixer is built to handle high temperatures, aggressive chemicals, and extreme pressures, making it ideal for critical mixing applications in sanitary and chemical environments.

Each unit is custom-configured to meet specific application needs, ensuring the right combination of motor, impeller type, and drive system for the most efficient performance.

Top Entry Agitator – Technical Highlights

Torque Capacity: Up to 50,000 in-lbs

Temperature Range: -100°C to 350°C

Pressure Rating: Up to 3000 PSI, with double-wall containment shells available

Mounting Options: Flange, Tri-Clamp, or Threaded Connection

Motor Options: Electric, variable speed, air, or hydraulic

Impeller Configurations: Designed for any process application

Material Selection: Available in various alloys, glass linings, and coatings

Advanced Monitoring & Control: Speed sensors, tachometers, and power monitors available

Sanitary Features:

- 15 Ra Polish for superior cleanability

- All stainless steel drive components

- Tri-Clamp ferrule for secure sanitary connections

Multiple Bearing Options for Various Conditions:

- Stainless steel lubricated and shielded bearings

- Hybrid ceramic/stainless dry-running bearings

- All-ceramic dry-running bearings

Certified for Hazardous Environments: ATEX certified for explosion-proof applications

Industries & Applications

The MagnaSafe MST Top Entering Mixer is designed for industries that demand high-purity, precision-controlled mixing solutions in sanitary and chemical environments.

Pharmaceutical & Biotechnology

Designed for fermentation, vaccine production, and biologics manufacturing.

Food &

Beverage

Ideal for ingredient mixing, dairy processing, and large-scale blending.

Chemical Processing & Oil & Gas

Built for reactor mixing, hazardous chemical blending, and toxic/dangerous reactions.

Research

& Development

Engineered for high-precision laboratory applications and high-pressure reactor testing.

Frequently Asked Questions (FAQ)

What makes the MST Top Entering Mixer different from other mixers?

The MagnaSafe MST Mixer eliminates mechanical seals, preventing leakage, contamination, and frequent maintenance issues. It is also ATEX certified for hazardous environments, making it a top choice for high-pressure chemical, pharmaceutical, and food processing applications.

How does Computational Fluid Dynamics (CFD) improve mixing performance?

What materials are available for construction?

Is this top entry mixer suitable for sanitary applications?

What are the maintenance requirements?

Does MagnaSafe offer custom configurations?

type, impeller selection, and mounting configuration for your specific process requirements.

Upgrade to a Leakproof, High-Performance Mixing Solution

Designed for uncompromising safety, durability, and efficiency, the MagnaSafe MST Top Entering Mixer delivers leakproof, maintenance-free performance for critical industrial applications.